Food freshness preservation technology, suppression of oxidation of fried foods, and healthcare products advancing in academic research. Currently, as of 2025, DENBA is expanding its business across various industries, including capital alliances with Itochu Corporation and SBI Holdings Inc., service provision of DENBA Health installed rooms at APA Hotels, the largest hotel chain, and joint development products with Hoshizaki Corporation, a major kitchen equipment manufacturer.

We have summarized in detail the technology of DENBA, which is starting to attract attention not only in Japan but also worldwide in the food industry.

Originally, DENBA technology was developed to maintain the freshness of food for a longer period. Human cells are each electrically charged, with the inside of the cell being "−" and the outside "+," maintaining stability. This is called polarization.

Disruption of this cellular balance greatly affects freshness and physical condition, causing pain and other issues.

Each substance has its own specific wavelength (vibration).

DENBA technology provides a wavelength that causes the water molecules to vibrate finely, allowing them to continue to vibrate naturally and without strain.

Explanation video of DENBA technology (12 minutes)

By retrofitting existing refrigeration and freezing equipment with DENBA products, DENBA technology provides fine electron vibration to the water molecules in food ingredients, allowing them to be refrigerated, frozen, and stored while maintaining their freshness.

Activating the cells of the food ingredients helps to maintain their freshness, suppress bacterial growth, and significantly reduce waste.

In addition, this technology is applied to frying equipment and health devices that can be used on the body to improve physical condition, gaining support from medical professionals, health-conscious individuals, and professional athletes alike.

Learn about DENBA Health

What is DENBA Healthcare? Is "water and electricity" related to maintaining health? [Product] DENBA Health StandardFood Freshness Preservation Experiment

This is a comparison experiment of food freshness preservation using DENBA products. It is evident that the appearance changes significantly with and without DENBA.

Strawberry comparison experiment

Beef comparison experiment

Grape comparison experiment

DENBA's Mechanism for Scientifically Suppressing Oxidation

— 3 Key Points —

DENBA's unique technology has succeeded in suppressing oxidation in the space, allowing freshness to be maintained for a longer period. It also leads to increased growth speed and higher yields.

Here are the three key points of DENBA's freshness preservation technology.

Generates wavelengths in all directions (360 degrees) to finely vibrate water molecules in the entire space

By providing a frequency wavelength that causes the water molecules to vibrate finely, the entire molecular cell vibrates. Since it affects the entire space, it is effective even if it is away from the mat.

Cells that are finely vibrating become activated through vibration

The wavelength causes the cells to vibrate, activating them. Additionally, vibrating cells generate heat energy, raising the temperature of the solid. *In the case of water, more intense vibration leads to boiling.

Suppresses oxidative bonding with cells by filling the space with electrons

Before oxygen atoms bond oxidatively with molecules or cells in the space, the filled electrons bond with the oxygen. This prevents oxidation.

It has been proven that DENBA affects everything in the space, extending the freshness of any food containing water.

Bacterial Growth Test on Food

‒ Bacterial Test of Pork After 1 Week ‒

Normal Refrigeration

General Bacteria Count: 5 million

DENBA

General Bacteria Count: 4,500

Features of DENBA Products

Reliability

Patent acquired in Japan and over 44 major countries worldwide

Convenience

Can be retrofitted to existing equipment, relocated, and designed compactly.

Uniqueness

Unique spatial potential technology that works in the space without touching. Maximizes the space and can be adapted to various locations.

Safety

PSE, CE certified. Effective with low voltage and ultra-low frequency

Versatility

Agriculture, fisheries, livestock, transportation, retail, food service, healthcare

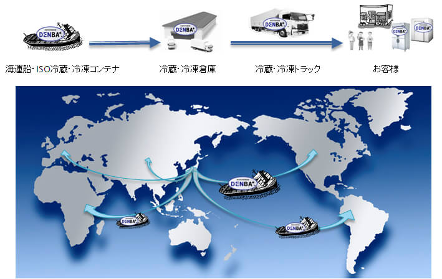

DENBA is Active Throughout the Food Cold Chain

DENBA technology has various positive impacts on the cold chain in Japan and worldwide.

It can be utilized throughout the flow from producers to general consumers, significantly reducing food loss.

In a world where calls for environmental improvement are growing louder, DENBA holds infinite potential and is an essential technology for the future.

What is a Cold Chain?

A cold chain is a logistics system that keeps perishable foods at low temperatures throughout the production, transportation, and consumption process. This technology has made it possible to distribute fresh foods widely and store them for long periods.

Wikipedia "Cold Chain"

DENBA's Role in the Cold Chain

Production + DENBA

Currently, the freshness of fresh produce declines rapidly after harvest, significantly impacting quality. By introducing DENBA technology, it is possible to maintain freshness for a long period, allowing for flexible shipment adjustments according to market demand and ultimately maximizing revenue.

Transportation + DENBA

Currently, food freshness declines easily during transportation due to temperature changes and the passage of time. By installing DENBA technology on transportation means, these issues can be resolved, allowing for the transportation of food to distant locations while maintaining freshness. This enables the provision of high-quality products to a broader market, expanding the market.

Processing + DENBA

In the current situation where the quality of processed foods heavily depends on the freshness of raw materials, introducing DENBA technology enables the preservation of raw materials' freshness. This improves the quality of processed foods, gaining consumer trust.

Storage + DENBA

Even in storage in refrigerators and freezers, the quality of food declines over time. By introducing DENBA's potential technology, the freshness of food in these storage environments is greatly improved. This technology significantly contributes to reducing food loss by minimizing quality deterioration during long-term storage.

Sales + DENBA

Currently, maintaining the freshness of food at stores is difficult, and food loss occurs easily. By introducing DENBA technology, the freshness of food lasts longer, extending the sales period. This not only is expected to increase sales but also allows for the provision of fresher food to consumers, leading to improved customer satisfaction.

As mentioned above, by introducing DENBA technology, the freshness of food is greatly improved at each stage from production to transportation, processing, sales, and storage. This enables flexible shipment adjustments, market expansion through quality maintenance, consumer trust acquisition, and food loss reduction, ultimately realizing overall revenue enhancement through DENBA's introduction.

These benefits ultimately contribute to environmental improvement and lead to the trust and development of the overall food industry, making it a product with infinite possibilities.

Various Locations Where DENBA is Introduced in the Food Industry

Cold storage room for agricultural products

Cold storage room for fishing vessels

Cold storage/freezing facilities for aquaculture

Cold storage/freezing facilities for food processing plants

Logistics cold storage/freezing warehouses

Cold/freezing trucks

Cold/freezing containers for import/export

Cold/freezing rooms for restaurants

Supermarket open showcases

Certifications Acquired

DENBA's Patent※Partial

Japanese Patent No. 5683032

Japanese Patent No. 5974377

Japanese Patent No. 6366882

Chinese Patent No. 1924981

Korean Patent No. 1759099

US Patent No. 9681677

Taiwan Patent No. 15683594

Australian Patent No. 2014382339

Singapore Patent No. 11201606465P

EU Patent No. EP3108752

Comparison of DENBA Freshness Preservation Products

DENBA FreshPro

For commercial refrigerators and freezers

$3,000.00 USD

Shipping included worldwide

Discharge Plates

Set of 3

Main Unit Size

W200mm×D150mm×H100mm

Discharge Plate Size

W260mm×D170mm×H6mm

Usage

This type is installed in commercial refrigerators of restaurants, processing plants, central kitchens, etc.

DENBA2.0

For large refrigerators and freezers (about 3.3 square meters)

$5,500.00 USD

Shipping included worldwide

Discharge Sheets

Set of 3

Main Unit Size

W300 x D200 x H108

Discharge Plate Size

W1260mm x D660mm x H10mm

Usage

This type is installed in large refrigerators such as prefabricated or warehouse refrigerators. One set covers an area of about 1 tsubo.

DENBA3.0

For large refrigerators and freezers (6.6 square meters or more)

$7,700.00 USD

Shipping included worldwide

Discharge Sheets

Set of 6

Main Unit Size

W360 x D230 x H113

Discharge Plate Size

W1260mm x D660mm x H10mm

Usage

This type is installed in large refrigerators such as prefabricated or warehouse refrigerators. One set covers an area of about 2 tsubo.

DENBA Fryer Products

DENBA Fryer

Up to 40% reduction in oil costs

$3,000.00 USDShipping costs extra

Discharge version

Set of 2

Fryer

Up to 2 tanks

Purpose

For reducing oil costs. For those who want to make fried food more delicious and healthy.